Technical Service – Generic & Specialties Amines

Amine Analysis

Detailed chemical analysis of your lean amine circulating solution is a key tool in determining the overall condition of the gas treatment system and monitoring parameters in order to identify the root cause of problems. The frequency of the sampling is established by mutual agreement between the customer and GP GasPack based on the volume of product supplied and customer’s particular requirements.

All samples are packaged in DOT-approved transportation kits to assure secure transportation of hazardous chemicals.

The laboratory analysis performed are:

- Amine Concentration or Alkalinity Test

- Total Nitrogen, used to detect all forms of nitrogen present on the sample, which contributes in the detection of degradation products

- Water by Karl Fisher Method

- H2S and CO2 loading

- Heat Stable Salts Determination and Speciation by titration and ionic chromatography

- Amine fragments.

- Cations analysis (determination of strong bases, like calcium, sodium, potassium).

- Metals in solution (iron, chromium, manganese and nickel).

- Ammonia content.

- Density and viscosity.

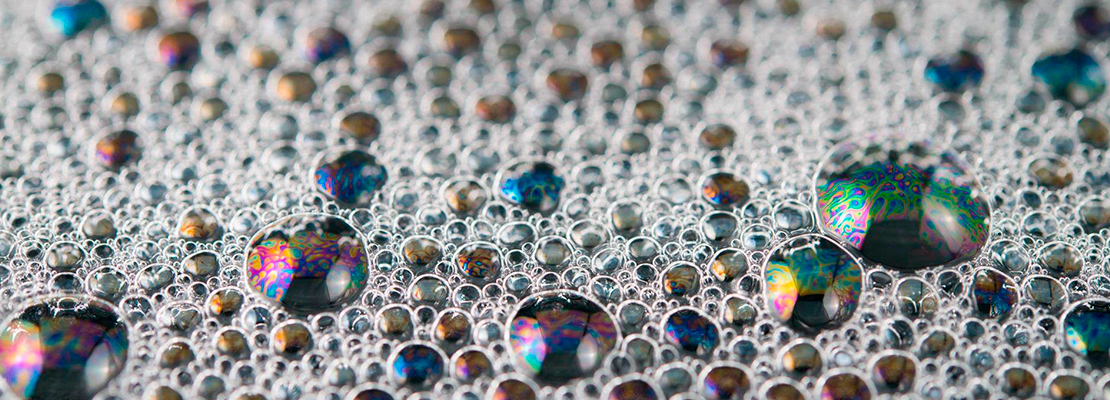

- Foaming tendency.

- Oil & Grease content.

- Total suspended solids.

Historical trends, using the results from previous recorded sample analysis. Follow up and interpretation of the results by our specialist team, tailored recommendations are provided.

Process Simulation

GP GasPack uses the software simulation package Promax V3.0, developed by Bryan Research and Engineering (BR&E), to model any new or existing gas treating application, including gas sweetening and dehydration plants, sulfur plants, dew point control systems, caustic treating, refrigeration process, etc. This software has been recognized globally as one of the best simulation programs in the market and it is considered as obligated reference especially for gas sweetening applications.

Troubleshooting

Our technical team is available to answer your questions. GP GasPack can assist you by carrying out root-cause analysis and providing recommendations for responding to issues such as off-spec treated gas, foaming, filtration, heat stable salts, high amine losses, high energy consumption, and corrosion.

Training Seminars

A technical seminar is offered to all personnel involved in the gas sweetening plants: operators, process engineers, supervisor, quality control personnel, interns, or any other people from the plant interested on the subject. The frequency of the seminars will be established according to the plant’s needs. The training covers basic aspects about amine chemistry, unit operations, troubleshooting, recommendation for better operation of the sweetening plant, etc.