Technical Service – Ammonium Polysulfide (APS)

Cyanide Mapping Technical Survey Protocol

As distributor of ammonium polysulfide (APS), GP GasPack wants to continue to supply quality products to those refineries that require APS. The best way to meet this goal is to conduct a technical survey to determine if excess cyanides are being generated in the refinery process units that typically generate cyanides such as the FCC, Coker or other processes that crack the hydrocarbon feed stream such as a Hydrocracker. These units may be a corrosion concern. The technical survey is also used to monitor the performance of existing APS applications. An annual technical survey (01 per year) is provided as part of the APS product supply. The survey involves on-site analysis of the various sour water streams generated by the process to determine the cyanide-based corrosion potential. The survey usually takes 2 days to complete.

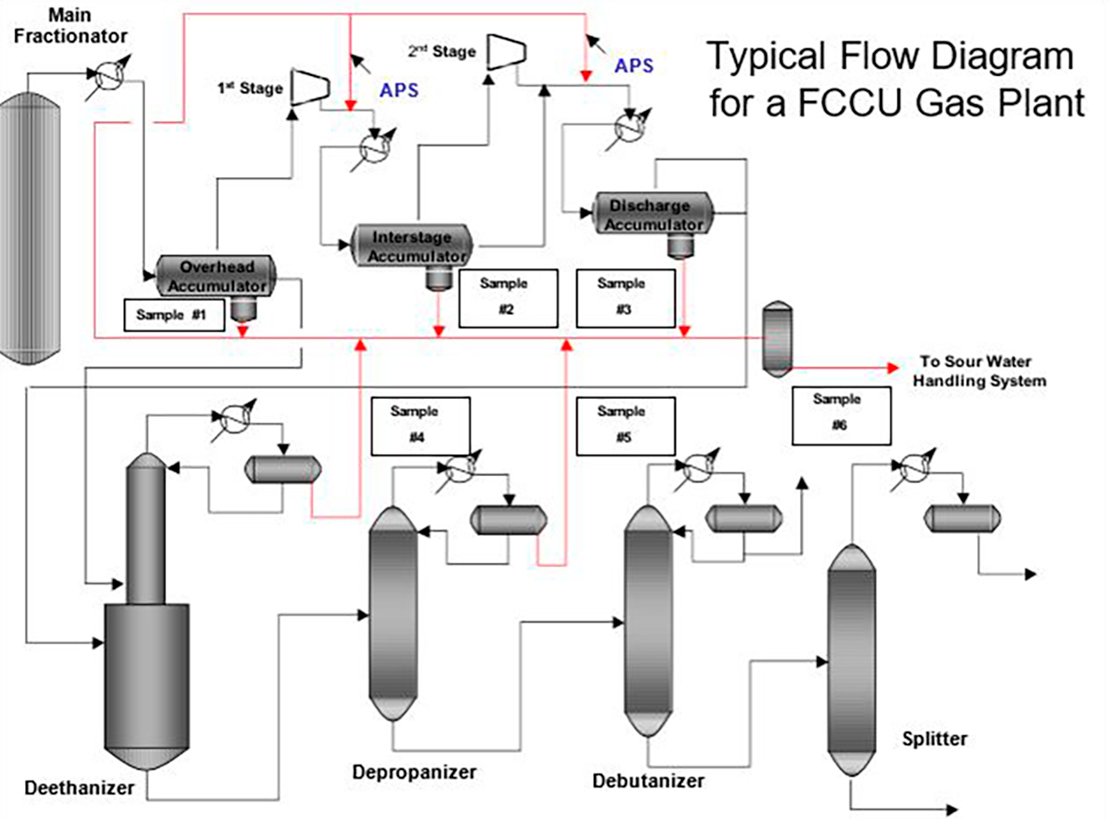

Figure 1 depicts a typical FCC unit as an example of the technical survey protocol. The usual format of the survey is as follows: [Additional survey days may be required beyond the normal format due to the number of sour water samples analyzed or merely because the potential application is new and we are not familiar with the process]

Day 1

- – AM Pre-Job planning meeting.

- – AM Completion of any on-site safety training.

- – AM Set up instruments, make standards and standardize analyzer.

- – PM Collect and analyze first set of samples.

Day 2

- – AM Collect second set of samples and analyze.

- – PM Collect third set of sample and analyze (if needed)

- – PM Job Close-Out/Review meeting to present initial results and make recommendations.

Survey Analytical Scope:

The sour water analysis includes the following testing:

- pH – Indication of the bisulphide-sulfide concentration

- Cyanide

- Ammonia

- Sulphide

- Color – Yields clues as to corrosion mechanisms present

- Turbidity – Provides information on the hydrocarbon –water separation.

The pH of the sample will be determined using a Ph meter. Cyanide will be determined by a proprietary method. Ammonia and sulfide will be measured spectrophotometrically. Color and turbidity are visual observations.

Any additional work required is determined and scheduled during the job closeout meeting. If excess cyanides have been found, our goal is to improve your corrosion control program. The items reviewed include the efficiency of your wash water system including application methodology, separation limitations and sour water handling limitations. A final report of the survey results and recommendations is provided 3-4 weeks after completion of the on-site visit or earlier if available. The survey final report typically includes the following components:

- A summary of the analytical results and wash water flow rates for the sour water streams analyzed.

- A discussion of the major trends of the analytical results.

- Recommendations for the APS application program if warranted by the survey results.